I am Kah Kiat Sham from the studio Future Works. The studio of Future Works reimagines the relation between energy, manufacturing and human activities. As a studio group, we aim to make the energy ‘noisy’ or visible to the public again as people have been taking energy for granted.

The proposed building is located at the site of Advanced Manufacturing Research Centre (AMRC). Currently, the site of AMRC is isolated from the city centre of Sheffield and most people travel to AMRC by car. Train station is proposed to connects the region with the city centre. With the train station, students and staff from the University of Sheffield will have greater accessibility to AMRC.

The proposed development will be known as the Advanced Remanufacturing Centre, which consist of science museum, research centre, train and monorail station, factory of the future and a landscape bridge. The factory of the future will specialise in the remanufacturing of aerospace components and small aircraft.

Remanufacturing is defined as the process of rebuilding or restoring an equipment to meet or exceeds its original manufacturer’s performance specification, using combination of reused, repaired and new components. It is known as the future of advance manufacturing as it can transform an old equipment into a completely new product, adding another 20 years or more to its lifespan.

The project is driven by 3 interlocking elements:

- the factory of the future,

- social and physical infrastructures that are bridging the local communities and workers which are separated across the region and the

landscape bridge which reconnects the region.

The landscape bridge promotes the idea of Sheffield as the green city. The landscape bridge will be the backbone of the development, connecting each of the proposed buildings together and reconnects the region which is separated by the railway and motorway. Train station and commercial spaces like supermarket are located at the north of the railway to ease the access of people from the AMRC side. The factory is integrated with the railway for efficient delivery of components and machines, allowing the factory to become highly configurable.

Landscaping – Factory as Destination

The masterplan aims to connects the AMRC, AMRC 2, Sheffield Business Park and a new wind farm to form the Advanced Manufacturing Cluster which specialise in renewable energy and aerospace sector.

The project aims to transform the Advanced Remanufacturing Centre and its surrounding site into destination for visitors, where the public can visit for leisure, witness the remanufacturing process of small aircraft and helicopters and gain knowledge on advanced manufacturing industry. The landscape bridge will connect the new recreational park at the south with the wind farm park and High Hazels Park at the northwest.

A constructed wetland is proposed to treat the contaminated industrial water. It is predicted that the surrounding area will be prone to flood in near future. The wetland will become the flood basin during extreme weather in the future. It can be one of the attraction point within the cluster.

Part of the existing golf club is converted into wind farm park to generates clean energy for the region. The wind farm park is open to the public for leisure activities like picnic.

Sustainable transport system – AMRC as the ‘factory’

Through site analysis, it is found that each of the factories are specialised in the manufacturing of different aerospace components. If these manufactured components are to be brought together, they could form most of the main elements of an aircraft, such as the jet turbine. The Advanced Remanufacturing Centre has the opportunity to source these components locally for remanufacturing process.

All the key factories within the region will be connected with monorail system, which can assist in the delivery of components from each factory to the Advanced Remanufacturing Centre. It aims to transform the Advanced Manufacturing Cluster into a ‘Factory’, where the Advanced Remanufacturing Centre and other individual factories within the cluster will be the ‘Machines’, linked by the monorail system to form the shopfloor. Each ‘Machine’ then produces individual aerospace components that will be delivered to the Advanced Remanufacturing Centre for the assembling process.

As the factory become a destination among the visitors, the monorail will be fully utilised by visitors and local residents to travel within the region. The monorail also connects the site with Meadowhall Interchange.

The Advanced Remanufacturing Centre will be the starting point for the AMRC to expand their site to the south.

Shopfloor:

The shopfloor drawings show the remanufacturing process of helicopter. The equipment or aircraft that exceeded its lifespan will be delivered to the factory via railway. It will then be moved from the train to the disassembly zone by machines or robots. On the disassembly zone, workers and robots will determine whether each disassembled parts can be reused or require replacement.

Worn-out parts that can’t be reused will be moved to the remanufacturing line where they can be remanufactured into new usable components. The reusable parts will be moved to assembly zone for reassembling with new components. New components required for the remanufacturing process are also delivered to the site via monorail, train or truck. The remanufactured small aircraft or drones can undergo flight test in the factory before it is delivered back to client via railway.

Factory of the future has to be highly configurable. Integration with the railway allow efficient delivery of machines to the factory for shop floor reconfiguration. The central space of the shopfloor will mainly consist of mobile robots which are not fixed to the ground.

Layout:

The building design aim to look into relation between the public and factory worker as well as the relation between the outdoor nature and working space. Public are allowed to get closer to the factory shop floor but yet separated from the working space. A viewing platform for the public is located at the first floor of the factory to allows public to have a closer look on the working environment and the remanufacturing process on shopfloor. The design introduces landscaping and daylighting throughout the building with an attempt to create a more relaxing working environment for the users. On the ground floor, the public realm of the train station is separated from the private realm of factory shopfloor by railway line. There are always direct visual connections between the private and public but the layout of the buildings restricts the public access to the private area.

The research lab and prototyping workshop on 2nd floor has direct connection with the factory shopfloor on ground floor. It is predicted that the factory in the future will relies on drones for delivery of components. Hence, the workshop on top floor can stay connected with the shopfloor on the ground floor. Public workshop will have direct connection with the factory shopfloor to ease the configuration of machines.

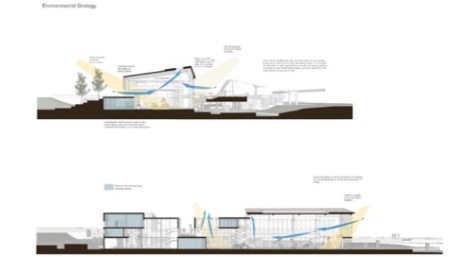

Environmental Strategy:

Some spaces within the building will not be heated via conventional heating system. Large volumetric spaces like the atrium of the research centre and factory shopfloor will relies on passive solar gain to heat up the space. The atrium is less likely to be occupied throughout the day by users and the shopfloor of factory of the future is likely to have more robots than human. The design encourages the change of human lifestyle to reduce the consumption of energy. Workers may consider to put on thicker clothing if they want to access the factory shopfloor during cold winter.

As a studio group, our proposals relate and are beneficial to each others. In my case, the Advanced Remanufacturing Centre can assist others’ factories by offering the service to remanufacture worn-out machines and equipment, increasing their lifespan.

Reblogged this on Future Works.

LikeLike